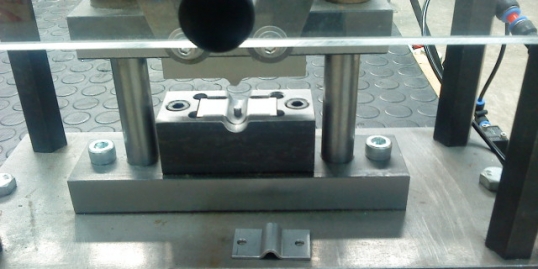

Pneumatic Press

To view an animation at the design stage please click here. The real life machine can be seen in operation here

The requirement was for a low cost machine that would form laser cut blanks into a ‘D’ shape. One day was spent on the design, using Pro Engineer it was possible to animate the assembly to check for interfering parts and also establish what force could be applied to the tool. In actual fact with the lever mechanism it is possible to apply up to six tonn with the pneumatic cylinder purchased off e-bay. The rest of the material was mainly in stock at the workshop. Machining took two days for the machine, one day for the bending tool then one day to assemble, this included building the pneumatic circuit and the integrated safety door. Closing the door keeps the operators hands occupied whilst the press completes its cycle.

The machine was easy to use and achieved a cycle time of five seconds. Different tools can go in the press to make different parts and the machine doesn’t take up too much room in the workshop. A good result!